The Only Guide for Turbochargers

Table of ContentsThe Basic Principles Of Turbochargers The Main Principles Of Turbochargers Not known Details About Turbochargers

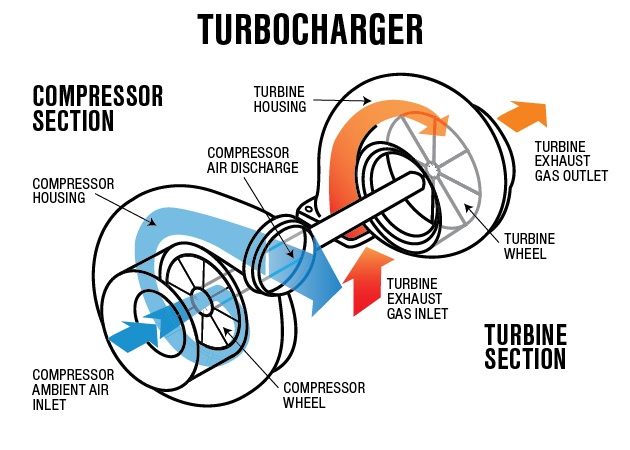

Forced induction gadget for internal combustion engines A turbocharger, informally referred to as a turbo, is a turbine- driven, forced induction gadget that increases an internal combustion engine's performance and power output by requiring extra compressed air into the combustion chamber. This improvement over a naturally aspirated engine's power output is because the compressor can force more airand proportionately more fuelinto the combustion chamber than atmospheric pressure (and for that matter, ram air intakes) alone - turbochargers.Today, the term "supercharger" is usually used just to mechanically driven forced induction gadgets. The essential distinction in between a turbocharger and a traditional supercharger is that a supercharger is mechanically driven by the engine, typically through a belt connected to the crankshaft, whereas a turbocharger is powered by a turbine driven by the engine's exhaust gas.

Twincharger refers to an engine with both a supercharger and a turbocharger. Producers commonly use turbochargers in truck, vehicle, train, aircraft, and construction-equipment engines. They are frequently used with Otto cycle and Diesel cycle internal combustion engines. Forced induction go back to the late 19th century, when Gottlieb Daimler patented the method of using a gear-driven pump to require air into an internal combustion engine in 1885.

This patent was for a compound radial engine with an exhaust-driven axial circulation turbine and compressor mounted on a common shaft. The first model was completed in 1915 with the aim of overcoming the power loss experienced by airplane engines due to the decreased density of air at high elevations.

Another early patent for turbochargers was obtained in 1916 by French steam turbine innovator Auguste Rateau, for their meant usage on the Renault engines used by French fighter planes. Individually, 1917 testing by the American National Advisory Committee for Aeronautics and Sanford Alexander Moss revealed that a turbocharger might make it possible for an engine to prevent any power loss (compared to the power produced at sea level) at an altitude of approximately 4,250 m (13,944 feet) above sea level.

The very first industrial application of a turbocharger was in 1925, when Alfred Bchi successfully set up turbochargers on ten-cylinder diesel motor, increasing the power output from 1,300 to 1,860 kilowatts (1,750 to 2,500 hp). This engine was used by the German Ministry of Transportation for 2 big traveler ships called the "Preussen" and "Hansestadt Danzig".

The Facts About Turbochargers Uncovered

Turbochargers were used on a number of aircraft engines throughout World War II, starting with the Boeing B-17 Flying Fortress in 1938, which utilized turbochargers produced by General Electric. Other early turbocharged aircrafts included the B-24 Liberator, P-38 Lightning, P-47 Thunderbolt and the experimental Focke-Wulf Fw 190 prototypes. Automobile and truck producers started research into turbocharged engines during the 1950s, however the issues of "turbo lag" and the bulky size of the turbocharger were unable to be resolved at the time.

Following the 1973 oil crisis and the 1977 Clean Air Act modifications, turbocharging ended up being more typical in cars, as a method to decrease fuel usage and exhaust emissions. In contrast to turbochargers, superchargers are mechanically driven by the engine. Belts, chains, shafts, and gears prevail methods of powering a supercharger, placing a mechanical load on the engine.

Adiabatic effectiveness is a step of a compressor's capability to compress air without including excess heat to that air. Even under ideal conditions, the compression process always leads to elevated output temperature level; nevertheless, more effective compressors produce less excess heat. Roots superchargers impart significantly more heat to the air than turbochargers.

In practical application the disparity in between the two can be dramatic, with turbochargers frequently producing 15% to 30% more power based exclusively on the differences in adiabatic effectiveness (however, due to heat transfer from the hot exhaust, substantial heating does happen). By contrast, a turbocharger does not position a direct mechanical load on the engine, although turbochargers position exhaust back pressure on engines, increasing pumping losses.

All About Turbochargers

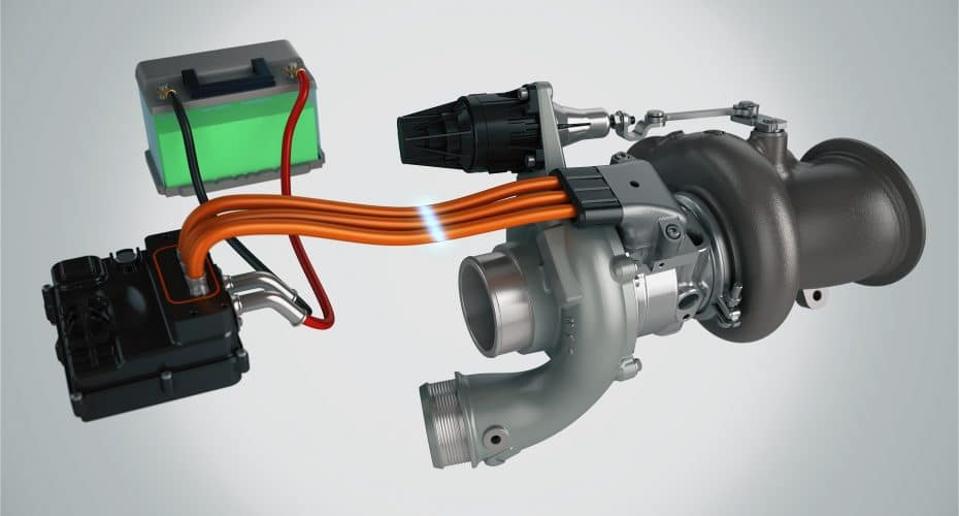

Only when the engine reaches adequate speed does the turbine area start to spool up, or spin quick enough to produce consumption pressure above atmospheric pressure. A combination of an exhaust-driven turbocharger and an engine-driven supercharger can reduce the weaknesses of both. This method is called twincharging. In the case of Electro-Motive Diesel's two-stroke engines, the mechanically assisted turbocharger is not specifically a twincharger, as the engine utilizes the mechanical support to charge air just at lower engine speeds and startup.

This varies from a turbocharger that uses the compressor section of linked here the turbo-compressor only during starting and, as a two-stroke engines can not naturally aspirate, and, according to SAE meanings, a two-stroke engine with a mechanically assisted compressor throughout idle and low throttle is thought about naturally aspirated. In naturally aspirated piston engines, intake gases are drawn or "pressed" into the engine by air pressure filling the volumetric space triggered by the downward stroke of the piston (which creates a low-pressure area), similar to drawing liquid utilizing a syringe. Resources turbochargers.